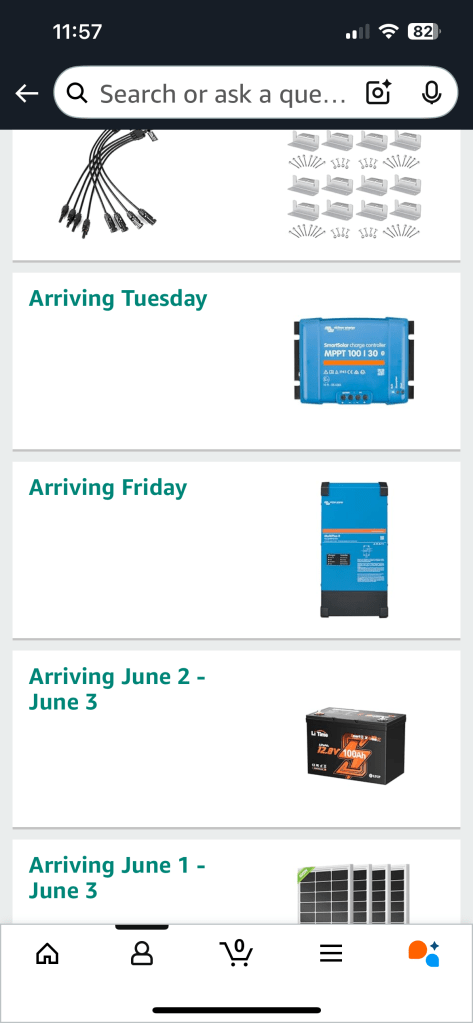

I had purchased a lot of equipment for the power system. I bought a Victron Multiplus II Inverter/Charger, Victron Solar Charger, 4 solar panels and a Lithium Battery. I need ALOT more components to get this all wired up.

I live in the Northeast so naturally it was the weekend so it rained so hard I nearly regretted not building an arc.

I ended up building a test bed for the Solar panels out of some extra lumber I had laying around. I also spent a lot of time researching the best methods for utilizing the products I had already purchased. I am going to make a special post about my system once I comes together.

I put a sheet metal plate on the wall behind the bathroom. It was going to be shelves, but I am going to try to fit the system in this spot. The inverter is HUGE, so it may need to be rearranged, this is why Im waiting to make a solar post, I want to make sure my system is safe and done right, not just for my own safety, but if anyone sees my system and tries to build their own, I want them to be making good choices too. I’ll try and share my knowledge on the subject as I learn, test, and double check everything.

I bought an external outlet for the bus, and some wire to handle that load to introduce shore power to the inverter. Wiring this inverter is nerve racking. Ive seen guys burn these up on YouTube, it’s a $1000 unit, so I really cant afford to do it wrong. I need some special ferrels to install the wire to the unit.

I cut a hole through the exterior, through the insulation and walls into the area I am putting the electrical system in. This is a 50 Amp Shore power inlet, the inverter is also a 50 am device so I can use the 4 wires that 50 Amp provides to use the two inputs on the inverter. To simplify the difference between different Amp rated outlets I’ll start with your typical household outlet.

Household outlets are typically 110(120) Volts, 15-20 Amps. You can run a fridge on one of these. Typical Household wire has three wires, a Positive, Negative, and Ground Wire…These are solid copper, which is not recommended for RVs because solid copper will break in a moving object over time…you can get the right sized braided copper for RV use, these are better because the wires are not solid and if one breaks there are 100 more still chugging along.

30 -50 Amp outlets are what you see at campgrounds.

A 30 Amp typically has similar wiring (3 wires) as household outlets with large wireamps to protect the 30 Amp current.

A 50 Amp typically has 4 wires and they are large enough to handle the 50 amp Current. 50 Amp outlets are what actually provide 2 110(120) Volt sources which is perfect for the Victron Inverter I bought which is 50 Amp and has two inputs for AC loads.

Heres the outlet and wire I used and the hole I cut to mount it.

I had to remove some stickers to install this, so I ended up removing all the lettering that I could around the bus (for when I prime the exterior)

Since I have to wait on hard to get components for the electrical, I cut up boards to make my bed frame. Ive been holding off until I was confident I didnt need to put anymore large sheets of plywood into the bus..I think im there.